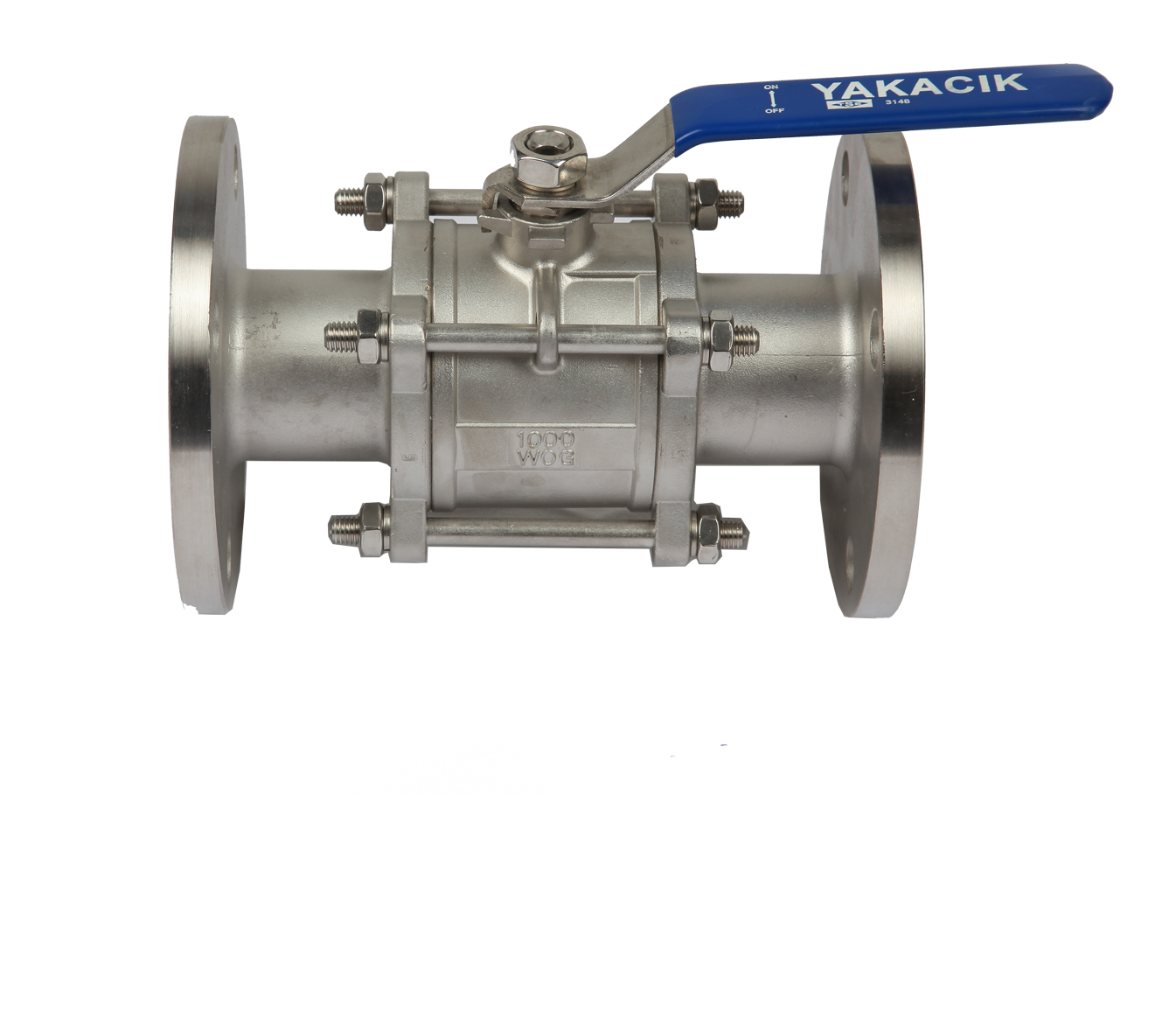

3 PCS BALL VALVE

Operating media

• Dusty media:Cement in facilities and silos

• Viscous media:bitumen(petrol industry and refineries), molasses(breweries)

• Fluids and gases in refinery- and tank-farm-construction(hydrocarbons,fuel,kerosene,oils)

• Liquid and natural gases

• Supply of compressed air for industry

• Drinking water supply: shut-off and control valves

• Superheated water, steam and head transfer oils: in caloric power plants and district heading supply

• Textile, pulp and paper industry: liquor

• Construction of tang lorries and wagons: Drain valves

• Chemical industry: acid-resistant ball valves for chemical solutions(acids, etc...)

Benefits

• Asbestos free

• Reliable, leak-tight shut off-in line and to the atmosphere

• Unique robots construction principle

• No wear on selling surfaces

• Insensitive to impurity

• Long service life and optimised life cycle costs

• Excellent regulation of flow

• Maintenance free

• PTFE Stainless steel disc spring

Fields of Operation

• District heating

• Energy producing

• Refinery

• Steel production

• Petrochemical

• Chemistry

• Production of tobacco

• Food and beverage

• Pulp and paper

• Tobacco, beer and sugar factories

The Sealing System

The ball together with the two sealing elements at the inlet and outlet of the ball valve, forms a single system the pressure of the medium process the ball agains the sealing element at the outlet part, but at the same time process the sealing element at the inlet part against ball. The reulting double sealing effect means increased service reliability. Both seals, act simultaneously. The sleeve surrounding the out edges of the diaphragm disc seals the ball valve to atmosphere.

Diameter DN 15-300 (1/2"-12")

Pressure PN 16 - PN 40

Tempature 400 °C max

Material GJL250 Cast Iron

0.7040 Ductile Iron

1.0619 Cast Steel

1.4308 Stainless Steel

1.4408 Stainless Steel

Connection Type Flanged. .. DIN EN 1092-2

Screwed... .DIN EN ISO 228-1

Socket........ DIN EN 12760

External Dimension Flanged DIN EN 558-1/1.seri

Screwed DIN EN 3202-4/M9

Socket DIN EN 3202-4/M9

Color Cast Iron – Grey

Cast Steel – Blue

Stainless Steel - Metalic