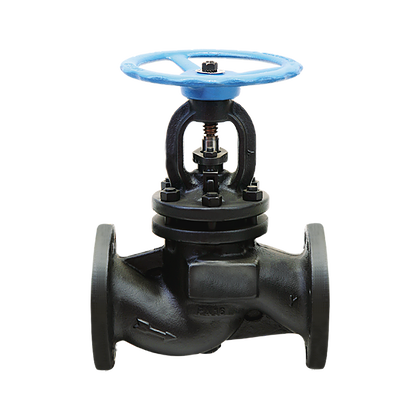

GLOBE VALVES

Operating Media

• Steam,

• Superheated water,

• LPG, pressured air,

• Boiled oil,

• Miscellaneous types of gauges(e.g, oxygen,hydrogen,nitrogen,etc.),

• Heat transfer oils,

• Chemicals.

Benefits

• Asbestos free,

• Reliable, leak-tight shut off-in line and the atmosphere

• Unique robust construction principle,

• No wear on sealing surfaces,

• Insensitive to impurity,

• Long service life and optimised life cycle costs,

• Excellent regulation of flow,

• Maintenance free,

• Valve remains in line if replacement of seat rings and internal parts are necessary.

Fields of Operation

• District heating,

• Energy producing,

• Refinery,

• Steel production,

• Petrocemical,

• Chemistry,

• Production of tobacco,

• Food and beverage,

• Pulp and paper.

The Sealing System

A stainless steel piston enclosed by two resilient valve ring forms the sealing system. The sealing area is the surface of the piston. The upper valve ring ensures tightness against the atmosphere, while the lower valve ring provides sealing across to ports.

Diameter DN 15-300 (1/2"-10")

Pressure PN 16 - PN 25 - PN 40

Tempature 400 °C max

Material GJL250 Cast Iron

0.7040 Ductile Iron

1.0619 Cast Steel

1.4408 Stainless Steel

Connection Type Flanged DIN EN 1092-2

Screwed DIN EN ISO 228-1

Socket DIN EN 12760

Butt Welded DIN EN 12627

External Dimension Flanged DIN EN 558/1.seri

Screwed DIN EN 3202-4/M9

Socket DIN EN 3202-4/M9

Color Cast Iron - Grey

Ductile Iron – Brown

Cast Steel - Dark Blue

Stainless Steel - Metalic